Comparison of design fatigue life values for cruciform joints: FAT class for crack at weld toe and from

fillet weld root; two values of misalignment considered, e = 0 and e = 0.1 t; maximum permissible weld convexity considered; continuous undercut omitted

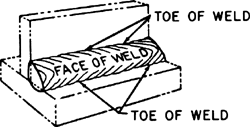

However, it also results in arc wandering on

fillet welds. The arc dances from plate to plate, so the puddle starts at the toes of the weld and flows toward the center.

But with the new generation of vehicles, aluminium is often used for car doors, and

fillet welds instead of overlap welds--Bautze said switching from overlap to

fillet welds could save a couple of hundred grams per door, which improves fuel consumption.

Razmjoo, "Interim fatigue design recommendations for

fillet welded joints under complex loading," Fatigue and Fracture of Engineering Materials and Structures, vol.

The majority of site connections were bolted, with connection plates

fillet welded to tubes wherever possible.

Productivity and quality benefits are found in applications such as narrow groove welds, pipe welds, clad overlay, square butt joints, high-speed

fillet welds, hard banding, and others.

As an example, the inherent deformations of a

fillet welded joint were calculated by the proposed method in the present study.

Weiler Corporation's controlled flare end brushes feature a uniquely trimmed crimped wire fill for more effective brushing action and greatly enhanced durability when cleaning

fillet welds, corners, bevels, channels, and slots.

In the visual inspection, throat thickness of

fillet welds was estimated.

The very smooth, consistent hybrid welds have also been shown to improve fatigue limits on

fillet welds by 300% over similarly sized conventional welds.