flywheel

flywheel

[′flī‚wēl]Flywheel

A rotating mass used to maintain the speed of a machine between given limits while the machine releases or receives energy at a varying rate. A flywheel is an energy storage device. It stores energy as its speed increases, and gives up energy as the speed decreases. The specifications of the machine usually determine the allowable range of speed and the required energy interchange.

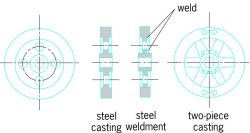

The difficulty of casting stress-free spoked flywheels leads the modern designer to use solid web castings or welded structural steel assemblies. For large, slow-turning flywheels on heavyduty diesel engines or large mechanical presses, cast-spoked flywheels of two-piece design are standard (see illustration). See Energy storage

Flywheel

a massive round part that is mounted on the driveshaft of a machine to reduce irregularities in its rotation during steady motion. A flywheel is a wheel with a heavy rim connected to a hub by straight spokes or a solid disk. It often also performs the function of a pulley or clutch disk.

The steady motion of most machines is characterized by periodic fluctuations of the angular velocity of the driveshaft. This is caused, on the one hand, by design features of the machine (for example, the presence of a crank gear in the kinematic chain) and, on the other, by the periodic change in the relations between the motive forces and the forces of resistance (for example, during the idle and power strokes). By accumulating kinetic energy during acceleration and yielding it during deceleration, a flywheel reduces the nonuniformity of shaft rotation to a level

permissible for normal operation of a machine. In inertial engines the energy accumulated by the flywheel is used to drive the machine (for example, in a gyrobus). Flywheels are usually cast from gray iron or, for velocities above 30-35 m/sec, from steel.