Oil free variants however do not inject oil directly into the

compressor stage, instead opting for faster rotation speeds, specialist air end coatings and tight machining tolerances to compress the air.

It was tested on a 146blade

compressor stage mounted on a rig in a wind tunnel [20].

NASA worked with General Electric to refine the design of the

compressor stage of a turbine engine to improve its aerodynamic efficiency and, after testing, realized that future engines employing this technology could save 2.5 percent in fuel burn.

The double-underscored variables are external inputs (evaporator inlet air condition, outdoor air temperature,

compressor stage number and supply air flow rate).

In order to simulate

compressor stage performance, the following nondimensional parameters are used.

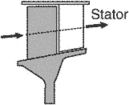

Axial

compressor stage performance is presented by the functional dependence of pressure ratio [[pi].sup.*] on the reduced frequency of rotor rotation ratio/[n.sub.red] and averaged by the value of the blade height of the angle of attack [i.sub.av] of the bladed disk grid.

This vented hot bleed air from the last

compressor stage of the engine directly into the aft avionics bay, causing significant fire damage.

The off-design behaviour can be analysed by some design parameters such as fluid incidence on the wheel blades, the rotor and stator section ratio, the free space parameter, the reduced speed and position of the

compressor stage on the Ns-Ds map.

The performance of a compressor is inherently deteriorated by different loses that occur at different sections of the

compressor stage. They are as follows: shock loss at an inducer inlet, wall friction loss within impeller channels, tip leakage loss, secondary flow losses, mixing loss at diffuser inlet, wall friction loss within a diffuser, sudden expansion loss at a scroll inlet, wall friction loss within a scroll.