engine cycle

[′en·jən ‚sī·kəl]engine cycle

ii. A specific activity in an engine such as from one start to the switch-off of the engine, one advance and retard of the engine, etc. For ease of record keeping within airlines, cycles are recorded as one takeoff and landing. The recording of cycles such as the times the engine has been started and switched off and the times the throttle has been advanced and retarded require special recording procedures for maintenance runs.

Cycle, Engine

a sequence of processes that regularly recur in an internal or external combustion engine and form the basis of the engine’s operation. A distinction is made between thermo-dynamic and actual cycles. In an actual cycle, as opposed to a thermodynamic cycle, allowances are made for heat losses, hydrodynamic losses, and so forth.

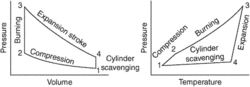

An engine cycle may be plotted as a closed curve in coordinates of the volume and pressure (V, p) or the entropy and temperature (S, T) of the working fluid. The area bounded by the contour is proportional to the work done. Figure 1 gives examples of thermodynamic cycles that are prototypes of the actual cycles of a carburetor engine (Figure 1,a) and a diesel engine (Figure l,b and l,c). The cycle of the carburetor engine consists of compression of the working fluid (adiabatic curve ac), addition of the heat Q1 (isochor cz), incomplete expansion (adiabatic curve zb), and rejection of the heat Q2 (isochor ba). The diesel cycle comprises compression of the working medium (adiabatic curve ac), addition of the heat Q1 (isobar cz), incomplete expansion of the working fluid (adiabatic curve zb), and rejection of the heat Q2 (isochor ba); or it may consist of compression (isotherm ac), addition of the heat Q’1 (isochor cz’) and Q” (isobar zz’), incomplete expansion (adiabatic curve zb), and rejection of the heat Q2 (isochor ba).

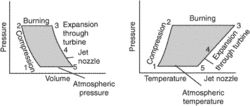

The gas-turbine cycle (Figure 1, d) with constant-pressure heat addition and complete expansion involves compression of the

working fluid (adiabatic curve ac), addition of the heat Q1 (isobar cz), expansion of the working medium (adiabatic curve zb), and release of the heat Q2 (isobar ba). A cycle with constant-volume addition of the heat Q1 is also possible.

Steam engines and turbines operate on the Rankine cycle. (See alsoCARNOT CYCLE and CYCLE.)