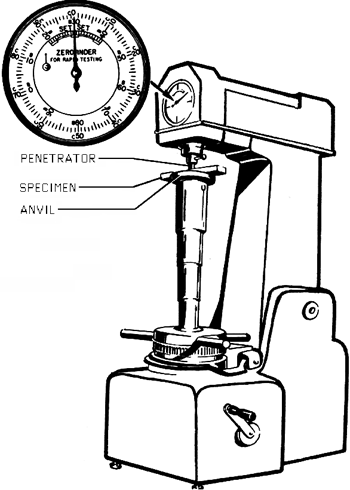

Rockwell Hardness Tester was used for 6 min at 650W to check the hardness of heat cure and self-cure acrylic resin before and after disinfection with microwave.

Its knives are made of Austrian steel with a

Rockwell Hardness of 64.

Also, you should find out the

Rockwell hardness of the blade, its steel composition, and whether it's a stamped or forged knife (see "Knife Lingo," right).

Hardness was measured according to ASTM D 785 using a

Rockwell hardness tester (Series 500, Page Wilson) in the R scale.

Mitutoyo America's HR-530 series

Rockwell hardness testers include the HR-530 for specimen heights up to 250 mm with depth to 150 mm and the HR-530L for specimen heights to 395 mm; depth 150 mm.

Rockwell hardness is measured on the net increase in depth of impression as a load is applied based on ASTM D 785 standards.

This series achieves

Rockwell hardness in the 40-52 HRC range.

The blade is made of high-carbon 440 stainless steel, heat-treated to a

Rockwell hardness of 57-59.

The originator of the

Rockwell hardness tester has introduced its Tukon 2500 Minuteman ELT automated Vickers/ Knoop hardness tester.

The indentation method with the

Rockwell hardness tester is the best to simulate defects in the glass samples.

At a thickness of 0.028 inch (0.7 mm), the Kydex sheet offers a notched Izod impact resistance of 3.5 ft-lb/inch (187 J/m) (ASTM D-276), tensile strength of 6000 psi (41 MPa) (ASTM D-638),

Rockwell Hardness of 98 (ASTM D-785), and heat-deflection temperature of 172[degrees]F at 264 psi (78[degrees]C at 1.8 MPa) (ASTM D-785).