butt joint

[′bət ‚jȯint] (electricity)

A connection formed by placing the ends of two conductors together and joining them by welding, brazing, or soldering.

(electromagnetism)

A connection giving physical contact between the ends of two waveguides to maintain electrical continuity.

(engineering)

A joint in which the parts to be joined are fastened end to end or edge to edge with one or more cover plates (or other strengthening) generally used to accomplish the joining.

McGraw-Hill Dictionary of Scientific & Technical Terms, 6E, Copyright © 2003 by The McGraw-Hill Companies, Inc.

butt joint

A plain square joint between two members, when the contact surfaces are cut at right angles to the faces of the pieces; the two are filled squarely against each other rather than lapped. See also: Joint

Illustrated Dictionary of Architecture Copyright © 2012, 2002, 1998 by The McGraw-Hill Companies, Inc. All rights reserved

butt joint

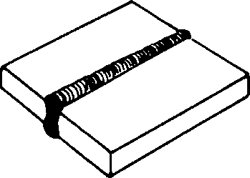

welded butt joint

butt joint formed by two boards

1. A plain, square joint between two members, where the contact surfaces are cut at right angles to the faces of the pieces; the two pieces are fitted squarely against each other rather than lapped; Also see oblique butt joint.

2.

McGraw-Hill Dictionary of Architecture and Construction. Copyright © 2003 by McGraw-Hill Companies, Inc.